A post by

Franz Haseidl

The brewing industry must work flat out to find ways of producing beer and other beverages without generating climate-damaging emissions. However, climate neutrality can only be achieved if breweries can utilise alternative options for heat generation on a broad scale and are electrified in some areas. This means investing billions of euros.

Released on 12/07/2024

A post by

Franz Haseidl

Franz Haseidl, IGS, one of the authors of the recent study on behalf of the Deutscher Brauer-Bund

In order to convert a brewery completely to alternative processes, large parts of a brewery must be restructured from scratch under the current framework conditions. This will not be possible without government incentives and support programmes, according to a recent study conducted by IGS on behalf of the German Brewers' Association. Experts believe that the brewing industry is facing a huge upheaval and an enormous test of endurance; small and medium-sized breweries in particular will struggle with the transformation in the long term.

In view of the legally enshrined goal of climate neutrality, the German Brewers' Association (DBB) commissioned IGS GbR to conduct a study on the energy transformation of the German brewing industry. IGS has been working as an engineering office in the field of energy and environmental technology for more than 30 years, primarily for breweries and malt houses.

The background to this is the legal framework of the Climate Protection Act that has been in force in Germany since 2019. This stipulates that complete climate neutrality must be achieved by 2045 and that greenhouse gas (GHG) emissions must be reduced by 60 per cent by 2030 compared to the reference year 1990.

The effects on the German industrial sector were analysed on the basis of nationwide pilot studies and possible solutions were identified specifically for the brewing industry. Based on the current energy status of the brewing industry, it was determined in what period, to what extent and with the help of which measures the transformation process can succeed. As a result, central concepts were presented and particularly relevant key topics, such as concepts for alternative heat supply, were analysed in more detail.

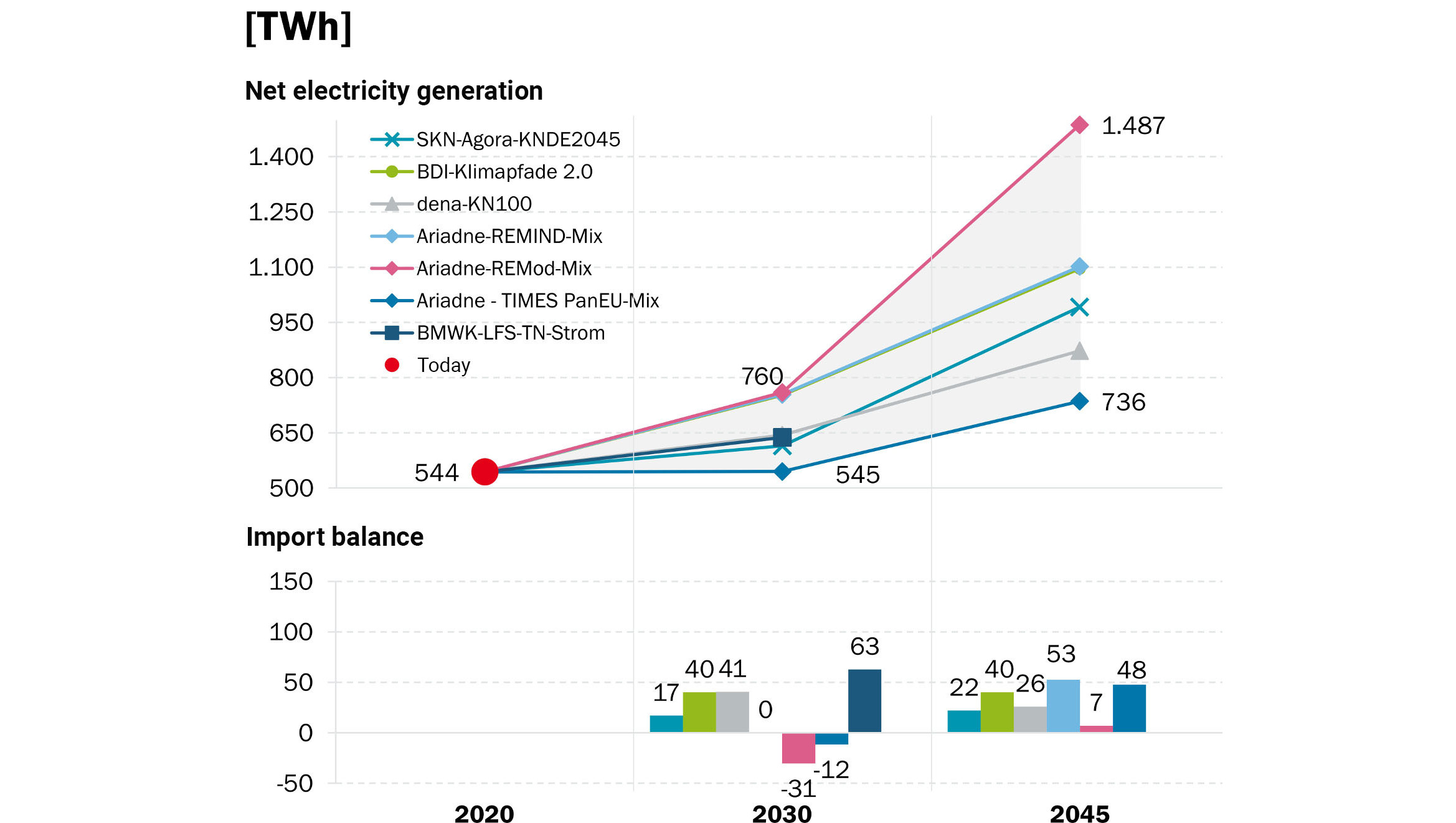

Development of the net electricity generation forecast in the CNS up to 2045; below: residual electricity imports

Comprehensive solutions for the energy transition in Germany are presented in the extensive climate neutrality scenarios of five major lead studies from industry, federal bodies and academia [1-8].

This was analysed in this study with regard to the industrial and energy generation sectors. Individual aspects of this are summarised below.

All of the lead studies consistently emphasise the great future importance of electricity. In all scenarios, the amount of electricity consumed will rise sharply by 2045, partly due to the displacement of fossil fuelled heat and the electrification of thermal processes.

In order to keep costs within reasonable limits with such a high demand for electricity, the main demand is for the maximum and fastest possible expansion of renewable energies - photovoltaics (PV) and wind power - up to the capacity limit. In this context, studies by the Fraunhofer Institute show that the electricity generation costs for new PV and wind power plants are already more favourable today than for fossil gas and steam power plants. According to projections, electricity costs can be kept at the same level as before the energy transition in the long term (provided the necessary infrastructure is available) [9, 10].

However, even with maximum expansion, domestic electricity generation will not be sufficient to make Germany energy self-sufficient. A certain amount of primary energy will remain, which will have to be imported in a suitable form (electricity, H2, etc.).

In the scenarios of the lead studies, renewable electricity is also used to produce energy-rich molecules for subsequent applications (hydrogen from electrolysis as the most prominent example). There are technological possibilities to produce a very broad spectrum of basic materials in the cascade electricity - hydrogen - methane - fuels - chemical raw materials to produce a very broad spectrum of basic materials from renewable electricity. However, it is recommended to use energy sources from the beginning of the cascade wherever possible, as the processing effort and thus the costs of the energy source increase with each additional step.

There are also clear results with regard to biomass. None of the scenarios forecasts a significant increase in energy production from biomass. The arguments cited for this include ecological reasons, but above all the lack of land efficiency of energy crop cultivation (land efficiency of biomass is 15 to 18 times lower than that of PV and wind). This means that electricity generation is generally to be favoured over the cultivation of energy crops [5,8,10].

The type and utilisation of biogenic fuels will change significantly. In the future, residual and waste materials will primarily be used to supply industrial processes, rather than energy and crop plants for the energy and building sector, as has been the case to date. The potential for wood biomass is limited in the long term by wood growth. In the medium term, it will be possible to benefit from current high wood stocks in forests, especially in rural regions with local supply structures.

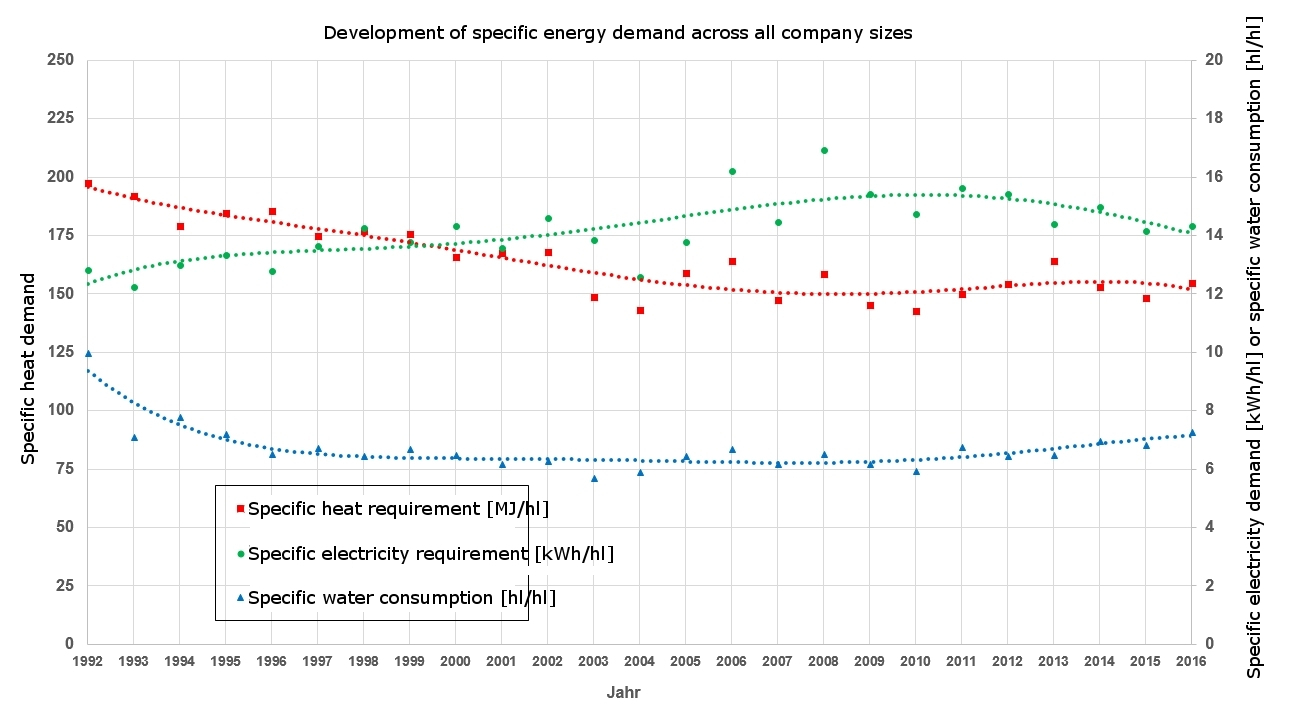

Development of specific energy demand values

The study describes the status quo of the German industry and the German brewing industry, particularly with regard to the energy sources used and the carbon footprint. In this context, the figure opposite shows the results of the analysis of specific energy demand values for German breweries.

The statistics are based on the energy comparison of companies, which IGS has carried out for around 300 breweries since 1992, with over 1200 individual analyses. For the participating breweries, the key figures obtained represent an important categorisation of the actual energy status. Thanks to the standardised procedure, this information is easily comparable and accessible at low cost. In the past, numerous starting points for the energetic and technological optimisation of operational processes have been identified and implemented.

It can be seen, among other things, that the specific heat requirement was reduced by 25 per cent on average in breweries between 1992 and 2000 and has stagnated since then (current figures from internal IGS statistics up to 2021 confirm this). Based on the respective best values of the individual company size classes and IGS's many years of experience in energy consulting, it was concluded that an average heat saving of more than 20 per cent is possible in the future if efficiency measures are consistently implemented. On the electricity side, the savings potential is estimated at around five per cent.

In the past, efficiency measures were often implemented very hesitantly for short-term economic reasons due to favourable primary energy prices. However, as efficient production structures are primarily effective in the long term, those companies that have invested early and consistently in their implementation are now at an advantage. High costs and planning uncertainties go hand in hand with the increased, strongly fluctuating energy prices. As a result, many measures that were not implemented just a few years ago are now viewed much more favourably, even against the background of short-term profitability figures. The starting points for energy optimisation in breweries are outlined in the study, but should be individually adapted to the respective operation in each case.

Matthias Kern, IGS, recommends an early start with company-specific concepts for transformation concepts

The above shows that the energy transformation will also be accompanied by major changes in the brewing industry. The timeline and the individual forms of development have not yet been finalised. However, the studies predict that an early start with an individual, company-specific strategic concept has great potential for creating long-term competitive advantages in terms of efficiency, costs and public image.

When it comes to technical implementation, it is clear that energy supply is becoming more complex and multi-layered overall. Breweries should pursue the following basic approaches:

Due to the predicted future importance of electricity, the study looked at the possibilities of electrifying thermal processes. The use of electric steam boilers and heat pumps is well known and technologically proven. The temperature levels in the respective brewery are decisive in this context - these must be adapted in each individual case. Storage systems ensure a temporal decoupling of production and consumption. The addition of photovoltaics on all suitable areas is a basic prerequisite for partial self-sufficiency in terms of electricity.

In suitable cases, (wood) biomass can be a basic component of heat supplies. Wood-fired systems now have a long market availability and are currently economically interesting due to favourable biomass prices in the case of wood chips (residual wood).

In order to further minimise the external energy supply, the material flows within the brewery must be utilised as effectively as possible. In this context, achievable degrees of self-sufficiency were calculated for the utilisation of residual materials. Residual materials contained in the wastewater can be converted into energy using various technologies (some of which have a long history on the market) and replace 5 to 15 per cent of the energy. The use of liquid residues from dealcoholisation plants increases energy self-sufficiency by up to 25 percent, depending on the proportion of AfB in the brewery and the process used. The greatest energy content is in the solid brewing residues, especially spent grains. By converting these, self-sufficiency can be increased by up to 50 per cent.

However, with the exception of individual cases, complete energy self-sufficiency (in terms of heat and electricity) is not the aim. A certain proportion of purchased renewable energy is usually preferable from an economic and ecological point of view in order to keep the investment and system costs within acceptable limits.

In addition to the already known and established technologies, the IGS and DBB study shows that numerous solutions are being worked on in research and development and that there are promising implementation options with varying degrees of market maturity. The technological maturity and individual suitability for the company in question must be examined on a case-by-case basis. Biorefineries, hydrothermal carbonisation, fuel cells and new concepts for cogeneration with renewable energies/biomass/residual materials are just some of the available options. With these tools, the energy transformation seems feasible, at least from a technological perspective.

It is important for companies to review the options on an individual, open-ended basis. Solutions that did not appear to make much sense in the past from a short-term perspective are not only economically attractive today, but will also be necessary in the future in order to comply with prescribed limit values, reduce CO2 levels and fulfil legal obligations.

Based on the current cost situation, the financial feasibility of a comprehensive transformation in the brewing sector is very difficult. Large companies are at an advantage as they can supposedly manage the transformation more easily over a 20-year period due to the human and financial resources they usually have. Small and medium-sized breweries, on the other hand, face considerable problems. Increasing cost pressure, falling sales figures in the industry and large corporations with pricing power are making it difficult to generate the necessary free funds. Further plant closures could be imminent. In addition to the companies' own initiative, political framework conditions and planning security will therefore be crucial in order to preserve the brewing industry in all its complexity and diversity. The public sector urgently needs to create the conditions that will enable all companies that approach this issue with the necessary seriousness and priority to overcome this major challenge.

The following requirements can be derived from the results of the pilot studies in order to enable companies to successfully implement the transformation:

Some of the points mentioned are already being implemented. Since the end of 2021, manufacturing companies have had the opportunity to receive funding for comprehensive transformation concepts (up to EUR 50,000). Energy audits are also eligible for funding for SMEs. Investments can be subsidised primarily via the Federal Office of Economics and Export Control (BAFA), but regional and EU funding is also available.

A first step on the way to GHG-neutral production must always be for the company to record the current status (energy and CO2-emissions). Based on this, a guideline with concrete measures and milestones to be defined should be developed. The transformation concept of the Flensburg brewery [12] is an example of this. Using such a guideline, the transformation process can be approached in a structured yet flexible manner.

This article is based on the technical article first published in BRAUWELT No. 11, 2024, pp. 387-391. You will also find the extensive list of literature sources there.

Quality assurance

A post by Dr. Jürgen Hofmann

Local heating network

A post by Monika Wels

Microbiological safety

A post by Lars Peuker

Automatisation

A post by Helmut Brunner