A post by

Ingo Pankoke

Head of Research Institute FIM / Returnable Systems and Testing Laboratory for Packaging

Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V.

The reliable availability of empties in the right quality is an important issue for the brewing and beverage industry. Empties schedulers and bottling planners in particular need to know how many empty crates and bottles are available or whether an "out-of-stock situation" could occur. This creates stress and may even cause economic damage. The digitalisation of returnable processes offers significant potential for optimisation here.

Released on 13/09/2023Updated on 13/08/2024

A post by

Ingo Pankoke

Head of Research Institute FIM / Returnable Systems and Testing Laboratory for Packaging

Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V.

In 2019, the VLB "Logistics" expert committee (Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V.) defined the topic of "empties management" as a task for a separate working group. The objectives were to analyse non-optimal empties processes and to examine the reasons for the lack of information on empties stocks required for filling planning. One of the most important results of the working group was the realisation that in most cases only a deposit value is determined for the empties - for settlement among those involved in the process chain. As a rule, there is no flow of information from the specialised beverage wholesalers (GFGH) to the beverage producers about the number, type and quality of the empties to be returned. Beverage producers can therefore only plan their filling processes with very imprecise "empties forecasts". This gave rise to the idea of developing a system that can record and pass on this missing information.

Although a system is available from earlier projects that would enable the automatic recording of stock levels simply by using transponders in returnable drinks crates, only around 2 million beer crates are equipped with corresponding RFID (radio frequency identification) labels as of 2023. It would probably take another five to ten years to equip all 200-300 million crates with a chip if a large-scale "retrofitting campaign" were to be launched in the short term. This system therefore cannot provide a short-term solution to the problem described above.

A proposal for an alternative interim solution was then presented at the beginning of 2020 as part of a working group workshop at Wilms SCT. The central idea was to equip the pallets of sorted drinks crates produced by GFGH with a barcode label, just like the full crates. The feared negative influences of wind, rain and UV radiation, which were expected for the uncovered empties yard, were to be eliminated by an RFID transponder integrated into the label. This idea then led to the "Di-Me-Pro" research project, which stands for "digitalisation of returnable processes".

Together with its cooperation partners Appelmann Getränke and Wilms SCT, VLB applied for funding under the IGP funding programme to enable the feasibility of a corresponding research and development project. The application was then approved on 1 April 2021 and the project was thankfully funded by the Federal Ministry of Economics and Technology (BMWK) under the funding code 16GP10301.

The project was launched with an inventory and process analysis at Appelmann, which was part of the R&D project as a pilot company. The completely manual sorting process at the empties yard without any infrastructure initially led to disillusionment among the project team. Without a power source within a 50 metre radius and without a roof that would have allowed an RFID printer to be installed within reach, how would it be possible to digitally record pallets? The only information available for sorting was a tally sheet, which was used to document the number of units sorted each day. It quickly became clear that a development outside the norm was needed.

The hardware

As the sorted empties are transported to the empties block using a forklift truck, the approach was chosen to also have the forklift truck or driver record the empties stock. For this purpose, the sorters are provided with a roll of "RFID stickers". Each sticker is printed with a consecutive number (0001-9999) to make it easier to recognise how many units have been sorted. When a unit with unmixed crates has been put together, this unit is given a "Bornbinder security tape", to which the RFID adhesive tag is then manually attached. At this point, the RFID chip has not yet stored any information.

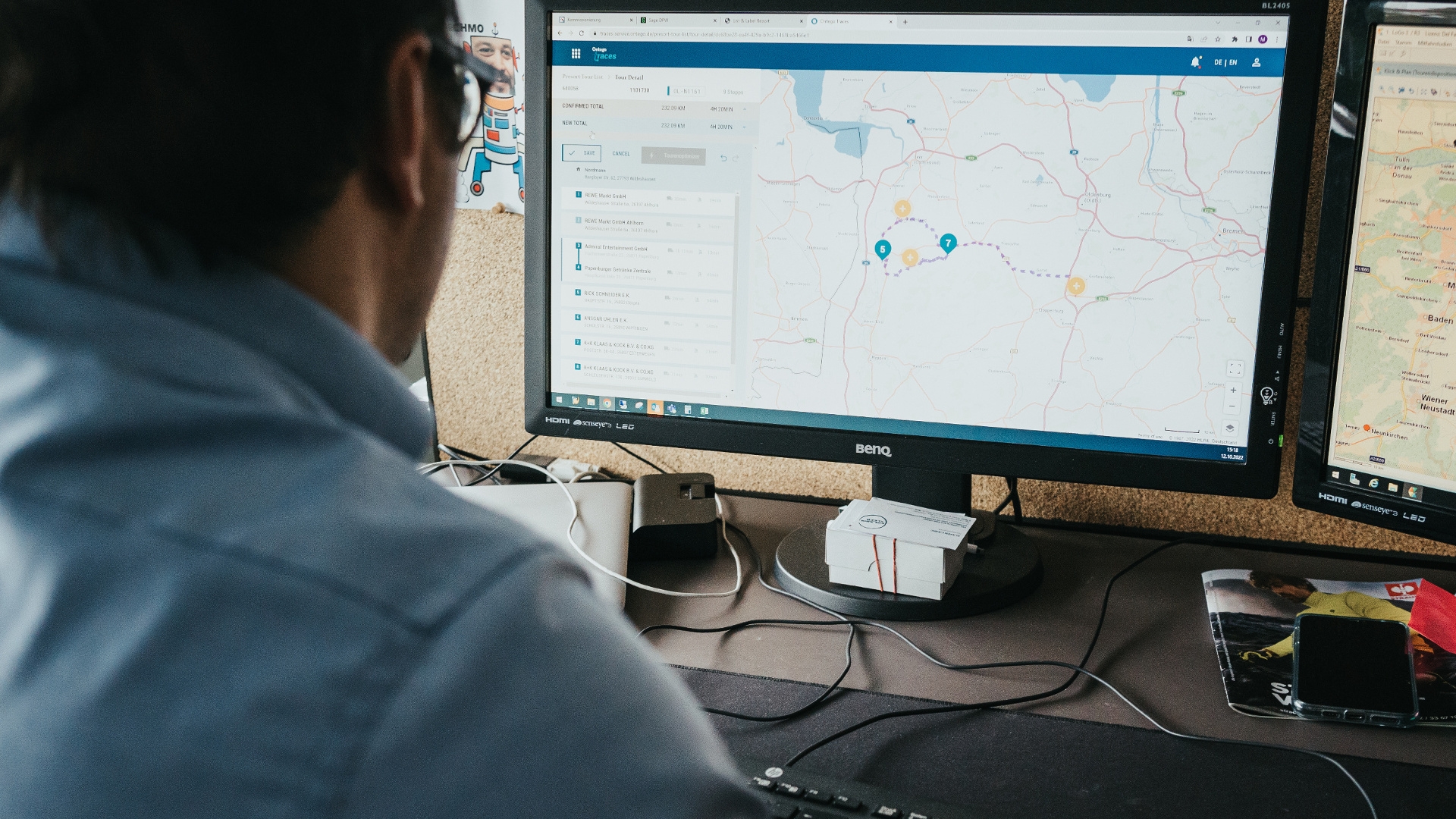

On the opposite side, the forklift truck was equipped with an RFID device that controls three reading antennas. The three antennas enable the transponders to be localised to the right, left or central pallet position on the variable double clamp. A proximity sensor, which is also mounted on the forklift, starts the RFID reader when a pallet is picked up and the transponders are detected automatically. The driver can then assign the respective empties item and the number of empties contained to the displayed transponder number via a mounted touchscreen tablet. In pilot operation, the printed brand of the crate (e.g. Gaffel or Reissdorf), the type of crate (e.g. 20x0.5 or 24x0.33) and the quantity of crates (usually 32, 40 or 48) are recorded. Communication with the database takes place via wifi.

The recorded information is fed into a database, which can then output the current stock and the movement data for the load units with the sorted containers.

As the tablet PC has a GPS module, the coordinates of the respective load units can also be recorded in an expansion stage. This means that in future it will not only be possible to see which items are in the empties yard, but also exactly where they are stored.

Another important component that was developed within the project is the standardization of the empties article numbers for "standard pool bottles" and their uniform designation.

The problem is that breweries that use uniform, neutral standard pool bottles each assign their own article number for this empties item. However, they are all the same empties item. In addition, the empties item designations in the data fields are sometimes quite different. However, in order to be able to summarize the stocks of the same returnable packaging across many companies, the naming must be standardized.

The working group decided on a procedure that would enable the VLB to assign a uniform article number (GTIN) for neutral standard pool bottles for the research project. For this purpose, 500 numbers from the article number range of Logipack Pool GmbH, which is also a member of the VLB, were reserved for allocation by the VLB (405947615000-405947615500). The bottles were recorded according to shape, filling volume, color and neck finish. The height, diameter and weight of each bottle were also recorded. The list currently contains 37 neutral standard pool bottles that are used for bottling in breweries. In addition, six dummy GTINs have been defined, which can be used as placeholders for unsorted bottles that are not exactly known. The list is freely available and can be downloaded from the VLB homepage. All users of the bottles can now replace their individual article numbers with the standardized numbers and enter them into their master data systems. The GFGH and empties sorting service providers can then use these numbers to record and communicate their respective stocks of bottles.

The final component of the project was to examine the utilization of data from reverse vending machines. To this end, discussions were first held with manufacturers of reverse vending machines to determine which data is recorded by the sensors as part of the deposit value determination process and how the data is processed by the machines. The individual bottles are recorded via parameters such as shape and weight, but also via the barcode of the respective item. The crates are recognized by their color and logo. Bottles in the crates are recognized differently. Sometimes only the height, sometimes also the color.

Overall, modern vending machines can provide information on the number and type of crates as well as information on the completeness of the bottles in the crates. However, this is only ever a "snapshot", as the contents of the crates can still be changed afterwards and the crates themselves are not sorted.

In general, consolidated data, for example from several vending machines in a region, could generate information about the "return behavior" of consumers. Deviations from normal return behavior could then be an indication of a possible fault in the return of empties and make this recognizable at an early stage.

Based on the findings from this research project, there are now plans to test RFID detection for empties loading units in a larger group of companies. Initial discussions on this were held at the last VLB Logistics Congress. The concept will be developed by the end of 2023. Beverage wholesalers who would like specific technical information on the system are welcome to contact the VLB.

Automatisation

A post by Helmut Brunner

Quality assurance

A post by Dr. Jürgen Hofmann

Delivery logistics

A post by Holger Wermke

Energetic transformation

A post by Franz Haseidl